CAPCO/CLP Celebrates the Completion of Emissions Control Project

Issued by:

CLP Power Hong Kong Limited

Making the Castle Peak Power Station one of the cleanest power plants among the world while meeting 2010 targets

Castle Peak Power Company Limited (CAPCO) today celebrated the completion of its Emissions Control (EC) Project undertaken at Castle Peak Power Station (CPPS) ahead of schedule. The EC Project gives CPPS a further lift of the already high-standard emissions performance, making it one of the cleanest coal-fired power stations in the world.

The EC Project has played an instrumental role in enabling CAPCO’s achievement of the HKSAR’s Government’s 2010 emissions reduction targets. With ongoing emissions reduction efforts including this important project, CAPCO recorded a material reduction of about 60% across all three emissions, sulphur dioxide (SO2), Nitrogen Oxide (NOx) and Respirable Suspended Particulates (RSP), in 2010 as compared with 1997, outperforming the overall targets set by the Government.

In 2002, the HKSAR Government and the Guangdong Provincial Government agreed to reduce the regional emissions of SO2, NOx and RSP by 40%, 20%, and 55% respectively by 2010, using 1997 as the base year.

CPPS is one of the few power generation plants in the world that are retrofitted with the three types of emissions control technologies while in operation. The EC project is one of Hong Kong’s largest engineering projects in terms of scale and complexity, taking more than 13.5 million man-hours to complete. The project also created around 9,000 jobs.

The EC Project includes retrofitting each of the four larger generating units (677 MW each) at the CPPS-B with three types of emissions control equipment: namely the Boosted Over Fire Air (BOFA), Selected Catalyst Reactor (SCR) systems and the Flue Gas Desulphurization (FGD) facilities. With the installation, SO2, NOx and the RSP will be substantially reduced.

Since the phasing in of the three retrofitted units in late 2009, coupled with the adoption of ultra low sulphur coal, the overall emissions performance of CPPS has been greatly improved. The last unit will be put in operation shortly.

In addition, gypsum produced during the desulphurization process can be re-cycled as materials used for construction industry such as cement and bricks, bringing extra environmental benefits to the society.

One of the greatest challenges for the project was to maintain reliable electricity supply when complex site work had to progress with vigilant logistics arrangement. Despite significant relocation, civil foundation, material handling and plant customisation works were required in different stages of the project, the Project Team kept an impressive safety record comparable to world standard during more than 40-project months.

At the ceremony, the CAPCO management sent their appreciation to all participating parties. They attributed the successful commissioning of the project to management determination, strong support from the government authorities and the collaborative efforts from the project team, the contractors and coal suppliers.

As coal-fired power generation will continue to play a role in local generation during the transition towards more stringent emissions requirements, contribution by EC facilities and adoption of ultra-low sulphur coal becomes critical in pursuing air quality improvement for Hong Kong and the Pearl River Delta. Looking ahead, CAPCO will continue to play its part and work closely with all parties in the community in every facet of ongoing air quality improvement efforts.

The EC Project is developed by the Castle Peak Power Company Limited (CAPCO), a 60-40 joint venture between ExxonMobil Energy Limited and CLP Power Hong Kong Limited as one of the initiatives for improving regional air quality in the Pearl River Delta. The project, accounting for an area of 40,000 square metres in a 24-hour operational power plant, is one of the largest engineering projects in Hong Kong in recent years.

About CAPCO

CAPCO is a joint venture between CLP Power Hong Kong Limited (40%) and ExxonMobil Energy Limited (60%) with three power stations in Hong Kong and a total power generation capacity of 6908 megawatts.

About CLP Power

CLP Power Hong Kong Limited is the largest electric utility in Hong Kong serving the business and domestic community in Kowloon, the New Territories, Lantau and most of the outlying islands. Operating a vertically integrated electricity generation, transmission and distribution business, CLP Power provides a highly reliable supply of electricity and excellent customer services to over 5.5 million people in its supply area.

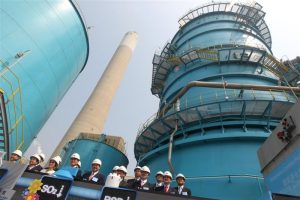

Mr Edward Yau, Secretary for the Environment of HKSAR Government (front row fourth left), Mrs Betty Yuen, Vice Chairman (third left) and Mr Richard Lancaster, Managing Director (fourth right) of CLP Power Hong Kong Limited, Mr David Ho, Director of Castle Peak Power Company Limited (third right), Mr Edmund Leung, Chairman of Energy Advisory Committee (second right) and Mr Leung Kin Man, Vice Chairman of Tuen Mun District Council (second left), together with all honorable guests officiated at the Emissions Control Project Completion Ceremony today. The Project has played a contributory role in uplifting the emissions performance of Castle Peak Power Station to become one of the world’s cleanest coal-fired power plants while achieving the 2010 emissions reduction targets set by the Government.

All guests posed in front of the desulphurization equipment of Emissions Control Project, to commemorate the Project’s completion which marks the new milestone for the emissions reduction performance of the Castle Peak Power Station.

Mrs Betty Yuen, Vice Chairman (left) and Mr Richard Lancaster, Managing Director (right) of CLP Power Hong Kong Limited introduced the 40-metre high gypsum store where the environmentally friendly by-product gypsum is kept. Gypsum was produced during the process of desulphurization. It can be recycled to make gypsum wallboard, bricks and other construction materials.

Picture shows the latest outlook of the Castle Peak Power Station after the retrofit of emissions control facilities. The power station is one of the few power generation plants in the world that are retrofitted with the three types of emissions control technologies while in operation. The Emissions Control Project that has taken more than 40 months and 13.5 million man-hours to complete is one of Hong Kong’s largest engineering projects in terms of scale and complexity.

– Ends –

For media enquiries, please contact:

Peggy Chan

Public Affairs Manager – Generation & Commercial

CLP Power Hong Kong Limited

Tel: (852) 2678 4973

Pager: (852) 71163131 a/c 8803

E-mail: pikkwan@clp.com.hk